By using powerful permanent magnets, our newly developed permanent magnet machines offer the highest efficiency with compact and lightweight design. Our engineering department customizes the machine design to meet your needs. Whether designed as “high torque machines” with low speeds and very high power densities or as “high speed machines” with very high speeds and extremely high power densities, we will work with you and for you to develop an optimized overall concept for almost any application.

Permanent magnet machine

- Voltages up to 15 kV

- Torques up to 4.000 kNm

- Speeds up to 20,000 1/min

- Power Generators up to 60.000 kVA at 1,500 1/min

- Electrical Equipment for Gas Explosion endangered Areas of Zone 1 and Zone 2

- Tailor-made Machine Design optimized for Customer Requirements

- LDW fulfill all Standards and Certifications such as IEC, EN, VDE/DIN, ABS, API, ANSI, BV, DNV, GOST, LRS

- High Torque machines with low speeds and very high power densities with the objective of avoiding the use of gearboxes or reducing the number of gear stages.

- High speed machines with very high speeds and extremely high power densities. Because of the higher power density compared to asynchronous machines and the lower losses of the machines at the same power, permanent magnet machines can generally be built smaller or more power can be generated from the same size. With smaller size, the rotor has a significantly lower mass moment of inertia, which is a great advantage for dynamic applications such as test benches.

- Permanent magnet machines have virtually no rotor losses compared to asynchronous machines and classic synchronous machines.

- Highest efficiency (low inverter current)

- Good thermal behavior (no rotor losses)

- Compact and lightweight design

- Simple construction (no slip rings and no rotor cooling required)

- Good field weakening behavior

- Optimized for highest torques and speeds

- In low and medium voltage

- Operation at frequency converter

- All common types of protection and cooling available

More questions about permanent magnet machines?

Please feel free to contact us

and we will respond shortly.

Applications

Our AC Motors are used in the following applications amongst others:

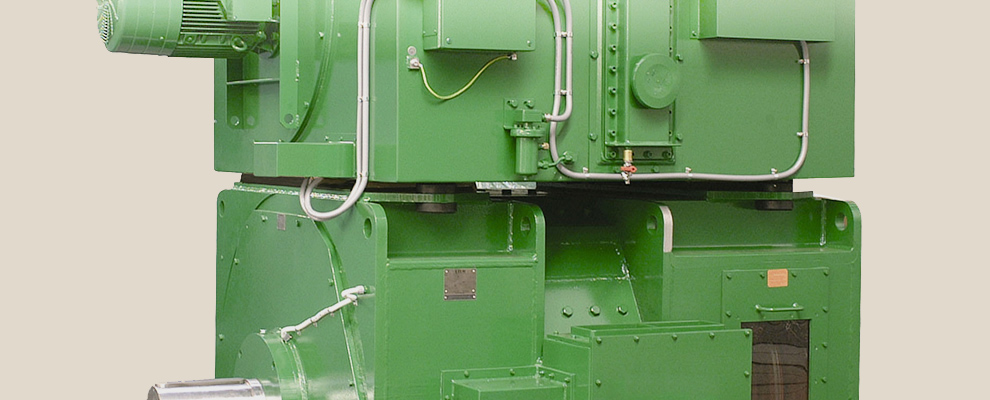

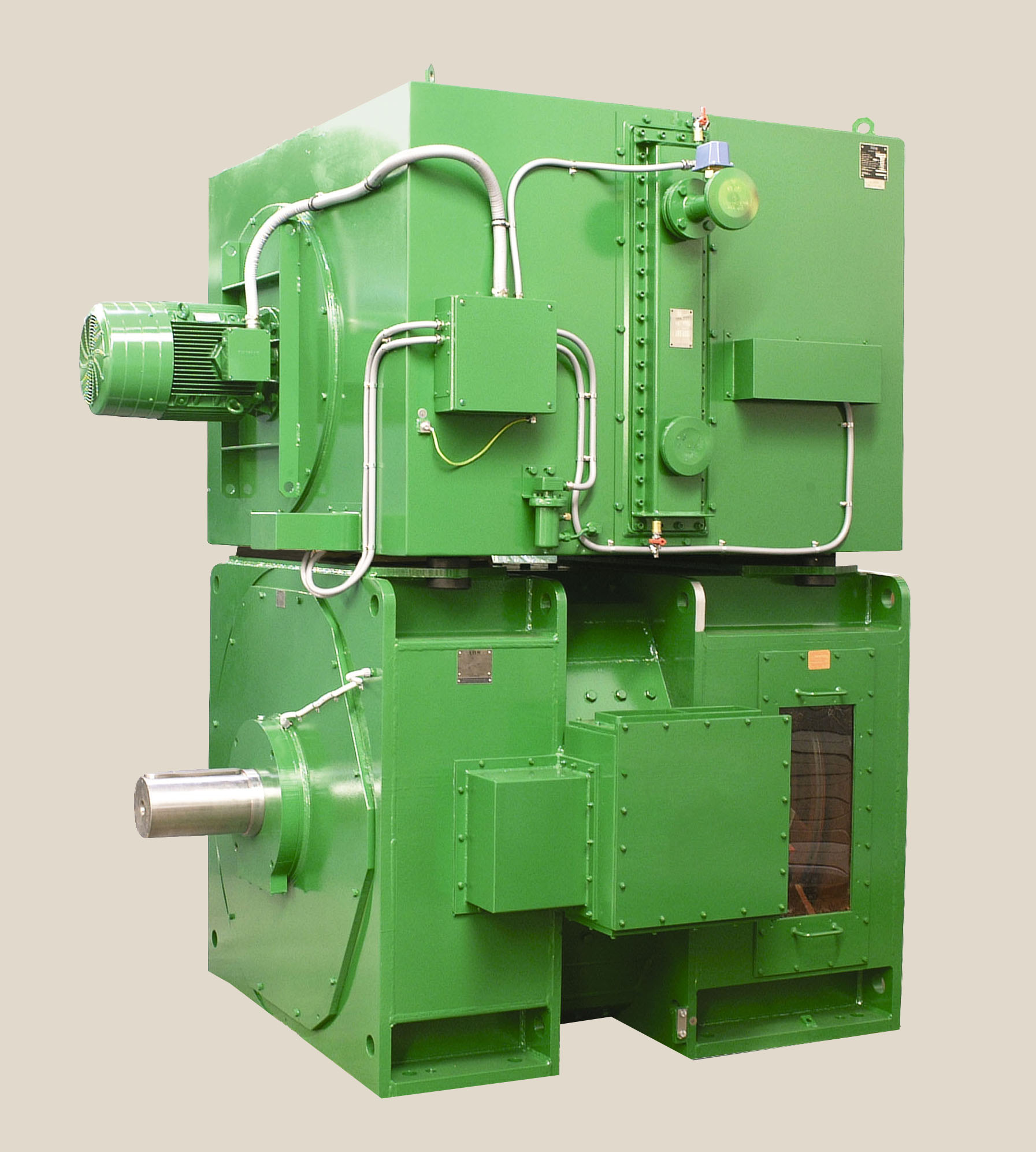

DC Machines

LDW is a leading competence centre for DC machines. Our expertise has developed and been proven over many decades. As one of the few globally active manufacturers, we are able to replace machines from other providers with one from LDW – taking into consideration electrical and mechanical specifications and adapting them to customer-specific applications. The machines are individually adapted to the respective application. Our spectrum ranges from small DC machines to very large products.

All machines are manufactured individually according to the requirements of our customers.

Continuous research and development has in recent years led to great improvements with regard to space utilisation and maintenance requirements of DC machines. In addition, the thermal and magnetic efficiency was increased and materials were optimised. The service life of brushes was significantly extended through this process.

LDW manufactures DC motors and generators in the power range from 10 to 8,000 kW.

Other characteristics of the machines:

- Shaft heights: 132 to 1,000 mm with angular designs, beyond this with round designs

- Torque range: 20 to approx. 900,000 Nm

- Rotational speeds up to 10,000 rpm

- Reliability under the most difficult operating conditions

- High control dynamics

- Compact, space-saving design

- Flexible mounting options

- Wide range of proven accessories

- Made-to-measure design

- All prevalent types of construction, cooling and protection

- Variants for explosion endangered areas of zone 1 and zone 2 in protection classes Ex “px” and Ex “pz” for pressurised enclosures

DC machines have a high power density, are especially compact and can be used in many different areas. Our machines are state-of-the-art and meet all current requirements of mechanical engineering and construction. DC machines from LDW have excellent control characteristics and clear control structures.

These machines run quietly, have outstanding concentricity properties and high run-up torques from standstill. DC machines do not have voltage peaks thus avoiding high insulation stress. They are distinguished by high electromagnetic compatibility. This means that normally no additional measures are required to minimise electromagnetic disturbances and increase interference immunity.

Other benefits:

- Easy to handle

- High adjustment range from low to very high rotational speeds

- Highly dynamic with fast current increase speeds

- Especially smooth concentric running

- Low volume

- Return supply capability into the network to save energy

- Low maintenance requirement

- High electromagnetic compatibility

LDW manufactures DC machines in all standard types of protection and cooling. We offer machines in horizontal and vertical designs that are adapted to the respective customer requirements. The angular shape of our DC machines makes them extremely compact and highly adaptable to the operating conditions on site. For shaft heights up to 315 mm the equipment can include square terminal boxes that can be rotated by 90 degrees. This allows the cables to be fed from an axial direction as well. Due to the optimal arrangement of the attached radial fans they have little outreach.

DC Motors from LDW are manufactured according to temperature class “H” (up to 180 °C). If the motors are used in accordance with class “F” (up to 155 °C), the service life of the insulation materials and therefore the winding is increased accordingly.

We offer a number of different options for optimal cooling of the machines: from enclosed, surface-cooled machines and internally cooled systems with external cooling through to air-air or air-water heat exchangers.

Our DC machines are designed to allow incremental encoders and standard brakes to be fitted. Since we use standardised components, the machines can be installed horizontally or vertically. Heat exchangers, pipe connections and a proven, comprehensive range of accessories can also be fitted as required. The brush apparatus has a user-friendly design so that the brushes can be easily replaced.

More questions about DC Machines?

Please feel free to contact us

and we will respond shortly.

Applications

Our DC-Motors are used in the following applications amongst others:

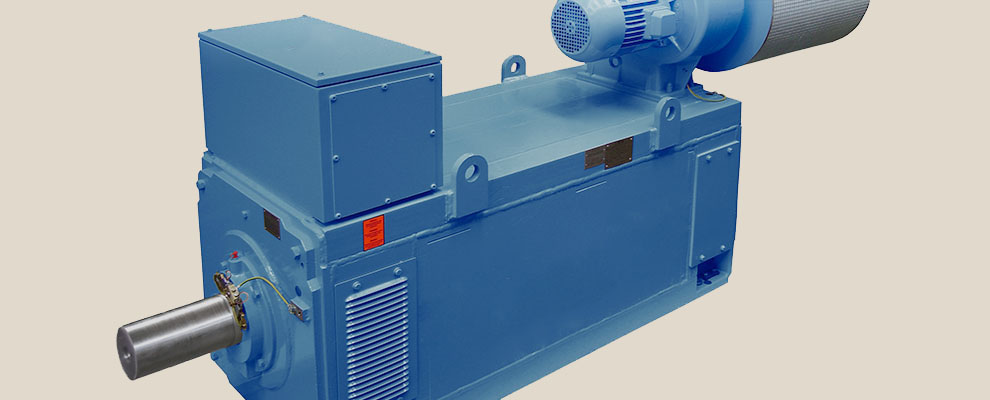

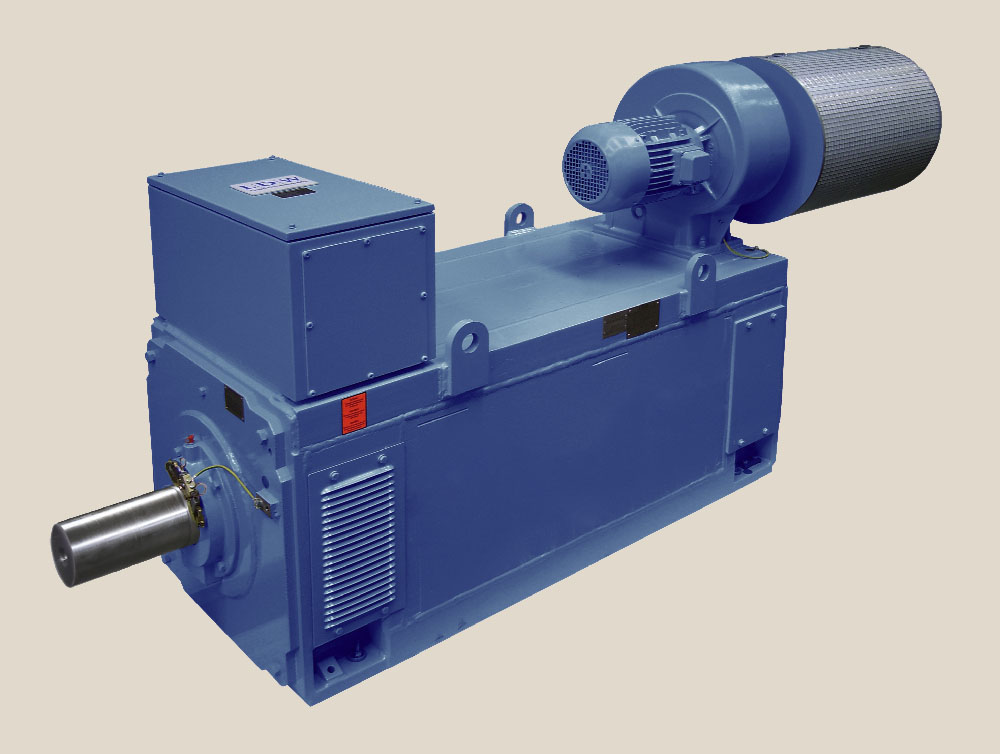

Compact asynchronous motors

Our compact asynchronous motors are distinguished by high torques in combination with a small size. They are highly dynamic with a low inertial moment, with a proven design as well as electromagnetically compatible for optimal, compact performance levels. We develop our compact asynchronous motors specially as speed-controlled drivers and for a supply from frequency converters.

They also consist of a flexible platform system and can be adapted to specific customer requirements. The housing is angular and jacketless. Being ventilated by a separately driven fan, the motors can constantly deliver the full torque over the entire speed range. The optimised control behaviour with converter operation means that these machines can replace DC machines.

LDW supplies compact asynchronous motors in an output range of 150 to approx. 2,500 kW at 1,500 1/min.

Other characteristics of the A5L series:

- Shaft heights: 200, 250, 315, 400, 450 mm

Our asynchronous machines are always state-of-the-art and meet the requirements of the IEC and DIN-EN standards as well as the EC Directives.

- High torque in combination with a small size

- Extensive speed control range

- Speeds up to 9,000 rpm

- High overload capacity

- Low mass moment of inertia

- Low weight as compared to standard motors

- All prevalent types of construction, cooling and protection

- Variants for explosion endangered areas of zone 1 and zone 2 in protection classes Ex “px” and Ex “pz” for pressurised enclosures

- High power density

- High control dynamics

- Compact motor design

- Adaptation to existing foundation (retrofitting)

- Performance according to insulation class H

- 24-h service through our qualified technicians

Compact asynchronous motors are supplied as cage rotors and in all prevalent types of protection and cooling. LDW manufactures these motors for installation as horizontal or vertical designs. They are suitable for frequency converter supply in the low voltage range.

More questions about Compact asynchronous motors?

Please feel free to contact us

and we will respond shortly.

Applications

Our Compact-Asynchronous Motors are used in the following applications amongst others:

Synchronous generators

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers.

Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.

LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.

Other features of the generators:

- Synchronous generators 4,000 kVA to 60,000 kVA at 1,500 rpm

- Synchronous generators 4,000 kVA to 25,000 kVA at 150 rpm

- Voltages up to 15 kV

- All prevalent types of construction, cooling and protection

- Variants for explosion endangered areas of zone 1 and zone 2 in protection classes Ex “px” and Ex “pz” for pressurised enclosures

- Increased safety Ex “e” and protection class Ex “nA” in accordance with ATEX Directive 2014/34/EU, IECEx Scheme and IEC/EN 60079 ff series of standards

Synchronous generators from LDW run reliably with a long service life even under the most difficult environmental conditions. Due to continuous product optimisation they are highly energy-efficient and economical to operate. In the event of a repair, the components are easy to access and replace. Our generators are also distinguished by low noise emissions.

Our synchronous generators are completed by an optimally adapted exciter system which we also supply with generator protection if the customer requires this. This ensures a high control dynamics. This is why they are safe to operate and have a long service life.

Other benefits:

- Individual design taking the power network conditions into account

- Adaptation to existing foundation (retrofitting)

- Symmetrical ventilation of active parts and winding, resulting in uniform warming and a longer service life of the machine

- High quality VPI-type insulation system for operational safety and a long service life

- Easily accessible and replaceable exciter machine for short downtimes in the event of damage

- 24-h service through our qualified technicians

Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

According to requirements our machines are designed as drum or salient pole machines. With salient pole machines, the poles can be replaced separately since they are individually attached to a cast rotor hub. To prevent problems related to parallel operation with other generators or the network, we design our synchronous generators with a generously dimensioned damper cage.

In addition, our customers can choose from a large number of digital controllers. On request, we supply complete generator control cabinets including regulator, generator protection and synchronisation.

The generators from LDW are designed in all prevalent types of protection and cooling as well as for indoor and outdoor installation. Even for difficult applications and environmental conditions as well as explosion-endangered areas we manufacture the machines to match these conditions perfectly.

LDW manufactures its synchronous generators with brushless excitation as standard. On request, we also supply synchronous generators with sliprings.

More questions about Synchronous generators?

Please feel free to contact us

and we will respond shortly.

Applications

Our Synchronous Generators are used in the following applications amongst others:

Three-phase motors

Our synchronous and asynchronous machines are distinguished by their high energy efficiency. The motors are reliable, safe to operate and robust. With our three-phase motors we offer special machines for almost any application. They are designed and built for the specific requirements of the respective drive application. We offer individually adapted motors – both in terms of electrical layout and mechanical design.

We provide made-to-measure units, for example, for existing foundations or special bearings to absorb additional forces. The power network conditions on site are taken into account for the electrical layout to ensure that only minor voltage drops occur and a reliable run-up is guaranteed. Our portfolio comprises asynchronous motors with cage or slip-ring rotors as well as synchronous motors with brushless or static excitation.

LDW supplies asynchronous motors with an output range of approx. 1,000 to 35,000 kW, and synchronous motors ranging from 4,000 to 50,000 kW.

Other features of the motors:

- Three-phase motors for voltages up to 15 kV, output up to 35,000 kW and constant speed

- Three-phase motors for voltages up to 10 kV at the converter, output up to 50,000 kW and variable speed

- All prevalent types of construction, cooling and protection

- Special types of cooling such as fluid jacket cooling up to outputs of 10 MV

- Variants for explosion endangered areas of zone 1 and zone 2 in protection classes Ex “px” and Ex “pz” for pressurised enclosures. Increased safety Ex “e” and protection class Ex “nA” in accordance with ATEX Directive 2014/34/EU, IECEx Scheme and IEC/EN 60079 ff series of standards

For the electrical layout we take into consideration special requirements concerning a reliable start-up current as well as possible voltage drops. In this respect we always aim for a design to optimise efficiency.

Our synchronous motors are completed by an optimally adapted exciter system which we also supply with motor protection on request. This ensures a high drive dynamics. They are safe to operate and have a long service life. Three-phase motors up to and including an axle height of 900 mm we manufacture with a patented tubular housing that reduces magnetic noise and vibrations. This makes additional sound-proofing measures superfluous. The running smoothness results in high operational safety for the entire drive system.

Other benefits of the motors:

- Individual design taking the power network conditions into account

- Adaptation to existing foundation (retrofitting)

- Symmetrical ventilation of active parts and winding, resulting in uniform warming and a longer service life of the machine

- High quality VPI-type insulation system for operational safety and a long service life

- Easily accessible and replaceable parts for exciter machine for short downtimes in the event of damage

- 24-h service through our qualified technicians

Our three-phase motors are durable, easy to maintain and have high efficiency levels. This makes them exceptionally effective. Our motors are produced in all standard types of protection, for indoor as well as outdoor installation.

Our machines can be variously equipped, for instance with an air-air or air-water cooler. They are designed for various applications. Even for difficult applications and environmental conditions we manufacture the machines to match these conditions perfectly. In aggressive environments suitable materials are used to prevent more intensive corrosion. We provide technical solutions for motors with a fixed speed on the network (up to 15 kV, start-up with choke or start-up transformer), but also motors for variable speed operation (up to 50 MW at 1,500 rpm) and power supply by means of all standard converter types and makes. LDW manufactures synchronous motors with brushless excitation as standard. On request, we also supply variants with brushes however.

If required, our technicians will design the motor bearings for additional axial or radial loads, for example. This also applies to three-phase motors with inclined positions (roll and pitch) which are required by the responsible classification societies. We construct our motors with cutting-edge FEM tools. The design, construction and manufacture of the motors is carried out in accordance with a sophisticated and comprehensive quality assurance and protection system based on our certification according to DIN ISO 9001.

More questions about Three-phase motors?

Please feel free to contact us

and we will respond shortly.

Applications

Our AC Motors are used in the following applications amongst others: